Quality products

TIMME represents exclusive small-series production focused on quality and timeless design. The brand is headed by a former professional athlete, multiple world and European champion in bikini fitness, Tímea Trajtelová, who has trained thousands of hours in her life and literally lives in sportswear. Thanks to their experience with a team of professional designers and constructors, they create truly functional, detailed, innovative pieces that stand out with their original cuts and materials that are like a second skin.

Every product starts with an idea, which is visually processed by our design team. The initial technical design is finalized simultaneously with the development or selection of a specific material, color, graphic or author's drawing and luxury details such as logos, patches, zippers, buttons, edging rubbers and other functional or design elements. In the next phase, we will bring our idea to life and create a real prototype of the new product, which is subjected to rigorous and detailed testing by our designers and professional athletes over the course of several weeks. We want to be sure that every product we make meets the highest functionality criteria, is durable, comfortable and its fit is designed to the last detail. After many training sessions, we receive feedback on the product, based on which subsequent prototypes are created. With each new prototype begins a new round of testing and processing comments until we are 100% sure that it is perfect and final. From the idea to the final product ready for production, it is a process that takes 6-18 months.

Production

The TIMME brand cooperates with proven manufacturers and uses high-quality materials and technologies. Our tailoring workshops are located in different parts of the world (Slovakia, Czech Republic, Italy, Spain, Turkey, China, etc.) depending on the type of product, processing, material and details we use for a given product. We regularly visit our factories to ensure that they have safe and healthy working conditions, do not employ minors and unqualified personnel, are clean and organized, and ensure high sewing quality and thorough product quality control.

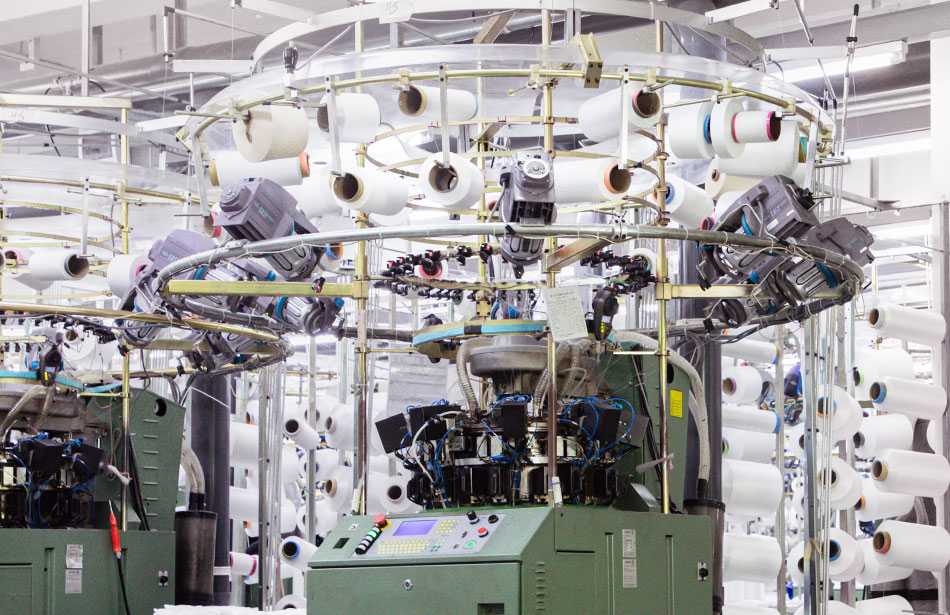

We prevent the creation of waste

We focus on creating timeless, high-quality and durable clothing that lasts longer and prevents unnecessary waste. Up to 90% of our offer consists of seamless clothing, which is knitted on a special machine into a single piece of fabric, which eliminates the waste material normally created during the production of clothing. In the context of the long-term production of clothing in general, it is a relatively specific and mainly revolutionary and innovative knitting technology on circular looms. It is a computer-controlled technology for producing one piece of clothing in one piece with minimal or no cutting. Compared to the previous conventional production of clothes, it drastically optimizes the amount of generated waste and significantly speeds up the production of the product in contrast to classic sewing on sewing machines. The absence of seams eliminates skin irritation, ensures a better fitting cut of the garment and provides an unlimited range of movement.

We focus on creating quality and durable clothing that lasts longer and eliminates waste. Within the company, we have established processes to limit it. All internal samples are carried by our employees. If the item does not meet the criteria set by us and cannot be put on sale, it is donated to women's homes, in the last case, we are ready to dispose of it ecologically. We use high-quality recyclable packaging for product packaging. Our goal is to provide our customers with an experience, but at the same time benefit by knowing how to use the packaging afterwards.

The significant scent of THE NINE

The basis of the significant scent of THE NINE are French ingredients originating from the most famous region of France, Provence. The final product is completed by a certified Czech manufactory.